EA-BT 20000 Series

Battery Tester: Benefit from battery tests with triple output

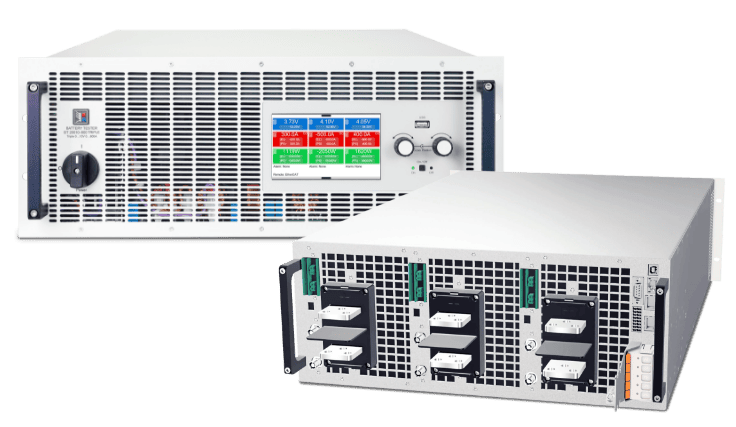

The New! EA-BT 20000 Series

Benefit from battery tests with triple output

EA-BT 20000 Series

Optimized for battery testing and battery simulation, the EA-BT 20000 Series (Battery Tester) are fully bidirectional supplies, allowing full control for both discharging and charging battery cells, packs, or modules. A max power of 30kW and the ability to parallel channels for up to 1800 A allows you to scale a solution to meet your needs. Included regenerative technology recovers energy during battery discharge or while simulating a charging battery and feeds that energy back into the local grid that would otherwise be lost as heat, reducing operating expenses and HVAC costs.

3 Channels – multiply your throughput: The EA-BT 20000 Triple battery tester brings three 10kW channels to a single 4U instrument. Each channel can be controlled individually to maximize test throughput, or paralleled together for higher current when test needs require.

| POWER | VOLTAGE | CURRENT |

| Up to 30 kW | Up to 2000 V | Up to 1000 A |

Key Features

High-Current

- 3 channels with up to 600 A or 1800 A in parallel

- Max. power 30 kW

- For simultaneous testing of up to three battery packs with 4 kW / 6 kW or 10 kW per channel

High-Precision

- For battery characterization and capacity measurements in production or R&D

- Measurement of voltage and current with high accuracy

- High control accuracy

High-Speed

- 1 ms communication speed for maximized data throughput

- Connection to control PC via GBit Ethernet, ProfiNet, CAN-FD, or EtherCAT™

Battery tests

- Testing of the electrical characteristics of a battery

- SOH (State-of-Health) for Second Life Classification

- End-of-Line (EOL) Testing

- Can be run in an automated test system or stand-alone

Battery simulation

- Simulation of batteries as single cells, modules or packs

- For optimal design of the energy storage system as well as the components to be tested

- When reproducible data is required

- With overcurrent protection (OCP) for safe function and protection of the connected loads

Battery recycling

- For complete discharge of the battery before final recycling

- Maximum possible deep discharge at high charge current, even at voltages below 2 V

The features at a glance:

- Wide range input: 208 V – 480 V, +10%, 3ph AC

- Active power factor correction, typical 0.99

- Battery tester, 2-quadrant for charging and discharging

- In discharge mode regenerative with energy recovery back to the grid

- Very high efficiency of up to more than 96 %

- Voltages from 0 – 10 V up to 0 – 920 V

- High power with up to 10 kW per channel

- Currents from 0 – 40 A up to 0 – 600 A per channel

- Flexible power regulated DC output/input stages (autoranging)

- Control modes CV, CC, CP, CR with fast transition Digital control, high resolution with 16bit ADCs and DACs, control speed selection: Normal, Fast, Slow

- Galvanically isolated share bus for parallel operation

- Share-bus for parallel operation

- Built-in interfaces with 1 ms communication speed

- Typical battery tester functionality integrated

- Integrated battery test mode, battery simulation

- Command languages and drivers: SCPI and ModBus, LabVIEW, IVI

Models Overview

Series

Power

Voltage

Current

Quote

EA-BT 20000 Triple 4U

4kW per ch. to 10kW per ch.

0 to 920V

40A per ch. to 600A per ch.

EA-BT 20000 4U

30kW

0 to 2000V

0 to 1000A

EA-BT 20000 3U

15kW

0 to 2000V

0 to 600A